Spray Foam Insulation

What is Spray Foam?

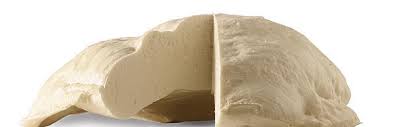

Spray foam insulation, or Spray Polyurethane Foam (SPF) is created using two separate chemical compounds, which are heated and then sprayed simultaneously using specialized equipment. Properly heating and mixing the chemicals produces a reaction that creates in spray foam insulation. The liquid mixture is sprayed onto the surface to be insulated. It then rapidly expands and cures in seconds, forming a solid, seamless, air barrier.

Spray foam is a superior method for insulating commercial and residential buildings alike, because it can be custom-fit to any architectural design or construction material. Spray foam prevents air and moisture intrusion, greatly reduces energy costs, strengthens the building structure and protects the internal air from mold, airborne pollutants and allergens for healthier, more energy-efficient buildings.

Top 10 Reasons to Use Spray Foam

- Saves much more money than it costs

- Reduces energy usage by 40-70%

- The only insulation that insulates, air-seals and acts as a vapor retarder in one step

- Will NOT hold moisture and will NOT allow mold growth

- Environmentally safe and ecologically friendly

- Suitable for all types of construction

- Creates a healthier, more comfortable and cleaner indoor environment

- Contains sound conditioning properties for a quieter indoor environment

- Forms a perfect fit to any size or shape cavity, cathedral ceilings, and any cracks, gaps or voids left by construction

- Lasts for the lifetime of your home or commercial or industrial building.

What Are The Benefits Of Using Spray Foam And Where Can It Be Used?

SPF has a multitude of performance benefits. It provides an insulation and air-sealing product all-in-one. The product is also known for controling noise transfer through and within the building, creating a quieter and more comfortable environment. For closed-cell SPF materials, there is also water and moisture vapor (humidity) resistance, providing condensation control. In fact, closed-cell foams are the only insulations that are rated as FEMA flood-damage resistant materials that can withstand floodwaters up to 72 hours.

The R-value and air-sealing capabilities vary based upon the product and the manufacturer. For example, low-density SPF (or “open cell”) has a comparatively lower R-value per inch and slightly less air-sealing capability than medium-density SPF (or “closed-cell”), but if your project can be met by the capabilities of low-density SPF, this solution could result in some project cost savings. However, if your project calls for a combined vapor, moisture and air-barrier with higher insulation value per inch, or the cavity to fill is not large enough for low-density SPF to reach the specified R-value, closed-cell could be your solution.